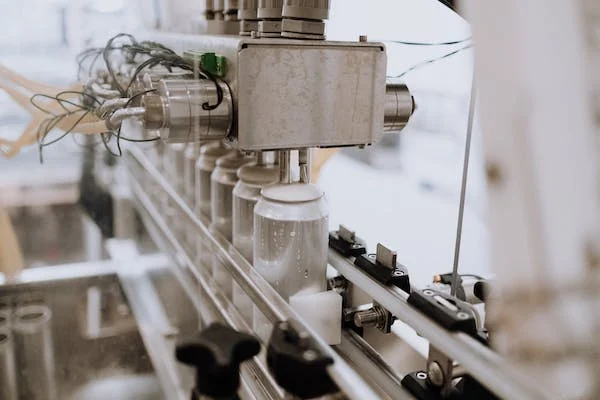

Are you in charge of the food processing facility? Do you need to package your food properly? Consider purchasing the can seaming machine. Your decision is a piece of equipment used to seal cans by attaching the cover and crimping it to create a tight seal. Continue reading to learn the benefits of purchasing this machine.

Increases Processing Speed

Typically, you invest in a can closer machine since it allows us to seal cans more rapidly and efficiently. It is quite useful for business owners who operate the food-processing unit because it seals all of the factory’s products swiftly and efficiently. Once we finish sealing, we will get our items out of the plant, onto shelves, or into customers’ hands.

A sealing machine is an essential piece of equipment for any company that manufactures products that require sealing for storage or shipment. Production speeds are increased by decreasing the time needed to seal each product. Since an induction sealer is a rapid and simple operation, it can consistently seal products at a high rate. Therefore, an induction sealer is a smart investment if you want to enhance production rates. It will not only help you package your items more efficiently, but it will also ensure that they are properly sealed and protected.

Ensuring Fresh Foods

Another key advantage of investing in a can seamer is that it helps ensure that factory-prepared food stays fresh for an extended period. If the cans are not correctly sealed, the food may spoil before reaching the buyer. Consequently, we will lose our clients’ and customers’ respect and confidence. To avoid this, we should invest in a can-sealing device that helps us maintain optimum product freshness. It increases product quality and earns a positive reputation among customers.

Impacts The Line Automation

The machine substantially impacts line automation, such as the pph butterfly valve manufacturers, and increases the efficiency of operations. There are multiple machines in a line, and the line automation process will be accelerated when the automatic sealing machine is added. The speed improvements will have a significant effect on the total production performance.

Reduces Costs Of Packaging And Minimal Product Waste

Although an automatic can-sealing machine may initially appear to be a substantial investment, it will drastically lower packing expenses in the long run. It will increase profitability and a stronger return on investment over time. Costs associated with sealing products would be reduced, making the firm more cost-effective. An airtight seal is a type of seal that is stronger and more reliable than traditional methods like caps or corks. Induction sealing is used in many different fields, like the food, beverage, and drug industries.

One of the best things about induction sealing is that it helps keep product waste to a minimum. When containers are sealed inside, they don’t need a cap or cork, which can cause leaks and make the food go bad. Also, the seal is less likely to break during transport or handling because it is so strong. It cuts down on the number of damaged goods that must throw away. Having an induction seal also helps food last longer on the shelf. The machine can operate with any mini jam jars wholesale, whether it’s made of glass or plastic.

Reduces Probability Of Error

When semi-automatic or manual methods are employed to seal items, errors may occur; when automatic devices are utilized, the likelihood of making an error is drastically reduced. It will help reduce costs associated with stock returns and preserve a great image for the business.

Utilized In Numerous Industries

Multiple industries can utilize the automatic can sealing machine, one of its primary applications. If you operate a diverse business, this machine will be quite handy and can use to seal a variety of products.

Prevent Leaks

By using a can seamer, we can prevent leaks, allowing us to save more money. If the can is not correctly sealed, it will destroy the plant and cause product loss. We will continuously receive client concerns. They start searching for products from competing brands. To prevent leaks, we must acquire the proper can seaming tool.

Simple To Use And Maintain

Because they are simple to run and maintain, induction sealers are a popular option for businesses. In addition, the sealing machines can generate a tight seal that aids in preserving the freshness of the stored products. Moreover, these machines are very compact, meaning they consume less energy and may be utilized for several purposes. Sealers even come with a portable carrying bag for travel between locations. In addition, the storage case increases the longevity of your induction sealer.

Conclusion

Most of the time, an automatic can seal machine is used in high-volume, automatic production lines. Since the device used to be a drilling machine, it is now a heavy-duty can seamer. Big companies love it because it is expensive, easy to make, and uses advanced technology. Large businesses are very happy with it because it is used to seal big cans quickly. Moreover, automatic can seal machines seal big cans in a stable and good way, which can help canned food last longer. Hence, purchasing a good quality can closer machine that works efficiently based on your business demands is important.